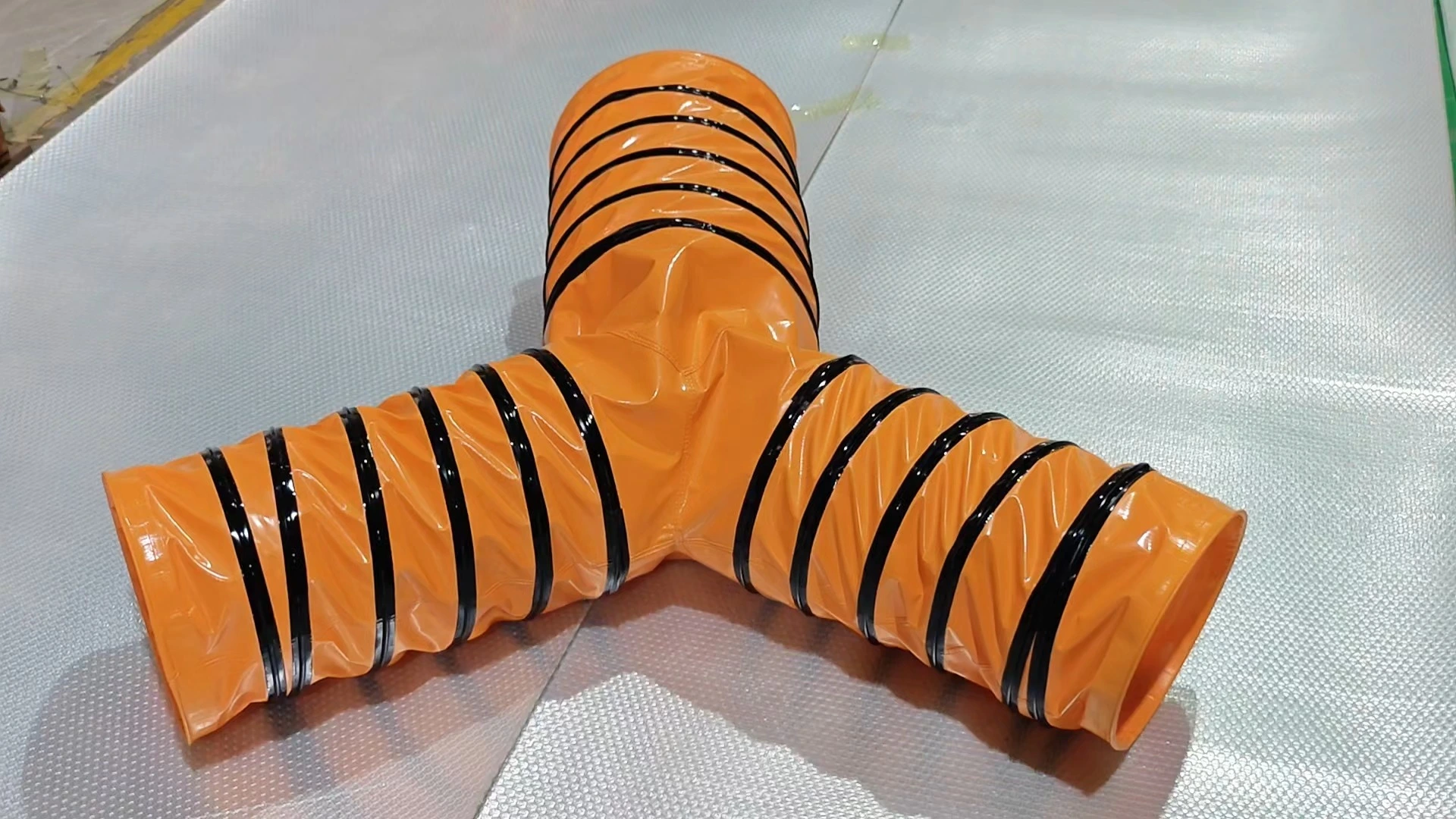

3 way pvc flexible Duct - Efficient Ventilation Solution for Multiple Outlets NUOENWEI

The main features of this 3-way PVC flexible duct in industrial environments include:

Multi-outlet design: multiple air outlets can be flexibly connected to meet the ventilation needs of large industrial equipment, machinery rooms or production workshops, ensuring even airflow distribution in all areas.

Durability: High-quality PVC material with good corrosion and chemical resistance, can work stably for a long time in various industrial environments, reducing the frequency of replacement and maintenance.

Flexibility and ease of installation: the duct has good flexibility, easy to install and move in a small space, adapt to complex working scenarios, saving installation time and cost.

Efficient air circulation: The optimized design of the duct structure can reduce wind resistance and ensure that the air passes through at a consistent flow rate, improving the overall efficiency of the ventilation system.

Contribute to safety and health: Effectively remove harmful gases, dust and odors from industrial environments, improve air quality and maintain employee health and safety.

3 way pvc flexible duct

The 3-way PVC Flexible Duct is a high performance ventilation solution designed for multi-directional air flow in industrial environments. Constructed of high quality PVC material for superior durability and corrosion resistance, this duct is able to withstand high temperatures and chemicals for use in harsh conditions. Its unique three-way connection design allows air to be efficiently directed to multiple outlets and is widely used in manufacturing, chemical, and food processing industries to maximize the efficiency and reliability of ventilation systems.

Related Parameters

|

Material |

PVC,thermal insulation material |

|

Diameter |

4’’-59’’ (Custom diameters available) |

|

Thickness |

0.4-0.65mm (Different materials vary in thickness) |

|

Length |

Custom lengths available |

|

Temperature range |

-15℃ to 80℃ |

|

Color |

Yellow,gray,green,blue(Custom color available) |

|

Connection |

Magic tape, zipper |

Product Advantages

1. Versatile Application: The 3-way design allows for multiple air distribution points, making it suitable for a variety of industrial settings, including manufacturing, chemical processing, and food production.

2. Durable Construction: Made from high-quality PVC, this duct is resistant to corrosion, chemicals, and high temperatures, ensuring longevity and reliable performance in harsh environments.

3. Easy Installation: The lightweight and flexible nature of the duct make installation and adjustments quick and straightforward, reducing overall labor time and increasing efficiency on the job site.

4. Improved Airflow Efficiency: The optimized design minimizes airflow resistance, enhancing the overall efficiency of the ventilation system and promoting consistent air circulation throughout the space.

5. Enhanced Safety and Health: Effectively removes harmful gases, dust, and odors, improving indoor air quality and contributing to a safer and healthier work environment for employees.

6. Cost-Effective Solution: The durability and efficiency of the duct result in lower maintenance costs and a reduced need for replacements, making it a cost-effective choice for long-term use.

7. Customizable Options: Available in various sizes and configurations to meet specific project requirements, ensuring compatibility with existing ventilation systems.

8. Lightweight Design*: Its lightweight nature not only makes it easy to handle but also reduces the structural load on duct support systems, simplifying installation.

Application Scenario

1. Manufacturing Facilities: In factories where machinery generates significant heat and airborne particles, the 3-way PVC flexible duct provides efficient airflow to cool equipment and maintain optimal operating conditions while removing dust and contaminants from the air.

2. Chemical Processing Plants: These ducts are ideal for handling the discharge of fumes and vapors. The corrosion-resistant properties of PVC ensure safety and durability when dealing with various industrial chemicals, helping to maintain air quality.

3. Food Processing Industry: Used in food processing plants, these ducts ensure proper ventilation and air circulation to prevent contamination and maintain hygiene standards. They effectively remove heat and moisture, contributing to safe food handling.

4. Warehousing and Logistics: In large warehouses, the duct can be utilized to provide targeted airflow in storage areas, helping to regulate temperature and humidity levels, which is critical for the proper storage of temperature-sensitive goods.

5. Automotive Workshops: In garages and automotive workshops, the flexible duct is perfect for directing exhaust air and fumes outside, promoting a healthier environment by reducing hazardous air pollutants.

6. Greenhouses and Hydroponics: In agricultural settings like greenhouses, the 3-way flexible duct assists in controlling temperature and humidity levels, ensuring optimal growing conditions for plants by distributing warm or cool air evenly.

7. Environmental Control in Clean Rooms: Applied in cleanroom environments, the duct helps ensure contamination-free conditions by facilitating controlled airflow, essential for industries such as pharmaceuticals, biotechnology, and electronics.

8. HVAC Systems in Large Buildings: It can be integrated into the HVAC systems of commercial buildings, providing efficient air distribution to various zones, enhancing comfort levels for occupants while maintaining energy efficiency.

Frequently Asked Questions