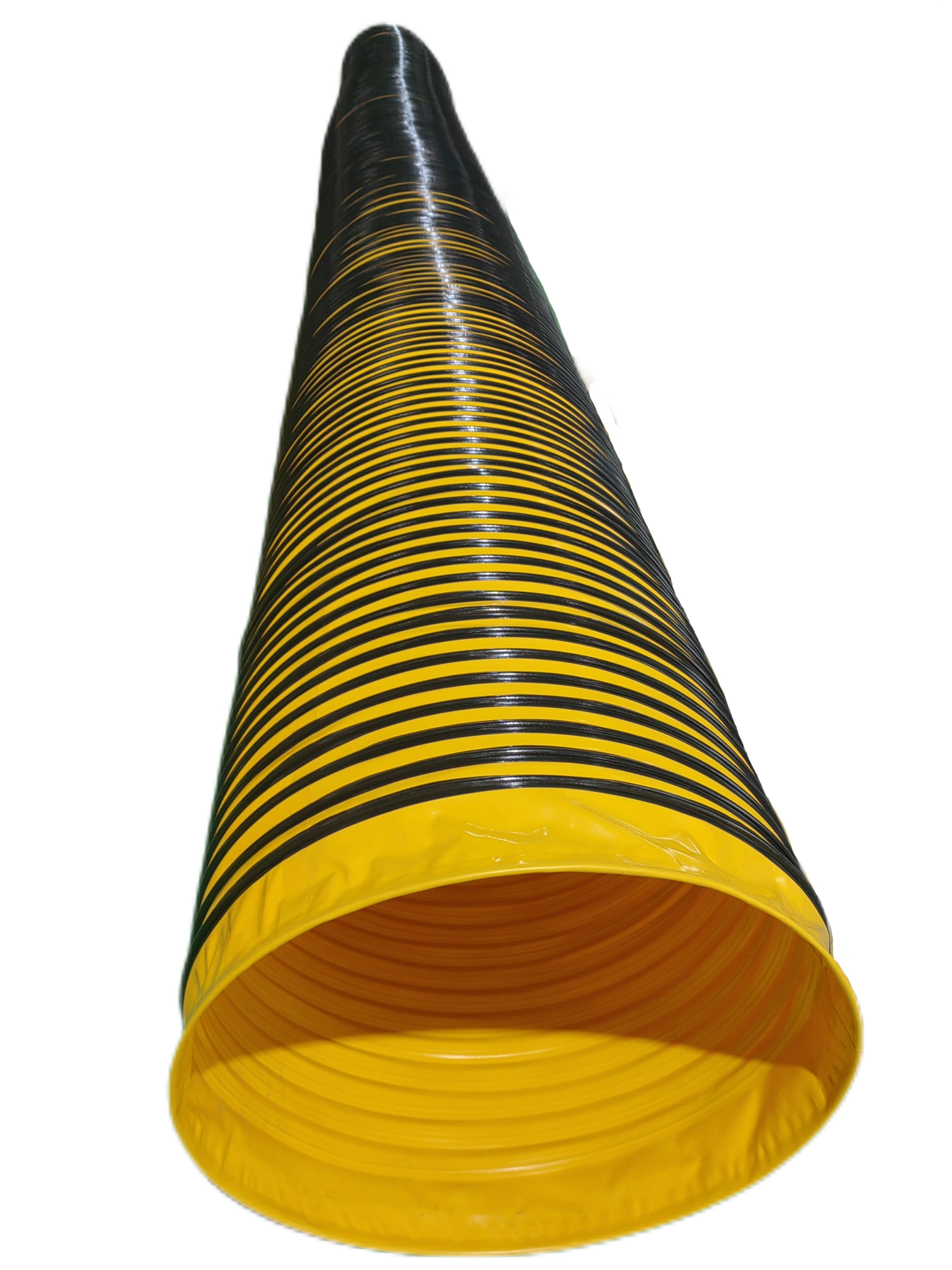

PVC Negative pressure flexible duct for mechanical equipment NUOENWEI

Material: Made of high quality PVC material to ensure corrosion, abrasion and high temperature resistance.

Structure: Ducts are generally spiral in structure with smooth outer surface, which can effectively reduce wind resistance and improve airflow efficiency.

Specification: The diameter, length and wall thickness of PVC negative pressure flexible ducts can be customized according to customers' requirements, and there are usually a variety of specifications to choose from.

Characteristics

Temperature range: Typically suitable for environments from -20°C to +70°C.

Flexibility: Easy to install and move, suitable for a variety of complex spaces.

Durability: The corrosion and compression resistance of the material ensures that it will not be damaged over a long period of time.

Installation and Maintenance: PVC negative pressure flexible ducts are easy to install, usually fixed with special fittings and clamps, and relatively easy to maintain.

pvc negative pressure flexible duct

PVC Negative Pressure Flexible Duct is a lightweight, durable ventilation duct designed for negative pressure environments. It is made of high quality polyvinyl chloride (PVC) material with good corrosion resistance and flexibility to adapt to complex installation needs. Widely used in industrial ventilation, air handling, exhaust and dust collection systems, it can efficiently transport air and keep the environment clean. The product is easy to install and maintain, suitable for various application scenarios.

Related Parameters

|

Material |

PVC |

|

Diameter |

100mm-1500mm (Custom diameters available) |

|

Length |

5m,10m,(Custom lengths available) |

|

Temperature range |

-15℃ to 80℃ |

|

Color |

Black(Custom color available) |

|

Connection |

Magic tape, zipper |

Product Advantages

Product Advantages of PVC Negative Pressure Flexible Duct

1. Flexibility: The duct's flexible design allows for easy installation in tight or complex spaces, making it adaptable to various configurations.

2. Durability: Made from high-quality PVC, it is resistant to abrasion, corrosion, and chemical exposure, ensuring a long lifespan even in harsh environments.

3. Lightweight: The lightweight nature of the duct reduces transport and installation costs, making it easier to handle.

4. High Performance under Negative Pressure: Specifically engineered for negative pressure applications, the duct maintains its integrity and efficiency, preventing air leakage.

5. Low Air Resistance: The smooth inner surface minimizes airflow resistance, promoting efficient air transfer and improved system performance.

6. Cost-Effective: Offers a balance of quality and affordability, making it a cost-effective solution for various ventilation needs.

7. Easy Maintenance: The duct is easy to clean and maintain, ensuring continued performance with minimal effort.

8. Customizable Options: Available in various diameters, lengths, and thicknesses to meet specific project requirements.

9. Wide Application Range: Ideal for industrial dust collection, HVAC systems, and laboratory ventilation, making it suitable for numerous industries.

These advantages make PVC negative pressure flexible duct an excellent choice for efficient and reliable air handling solutions. If you need more information or specific applications, feel free to ask!

Application Scenario

The application of PVC negative pressure flexible air duct in mechanical equipment

1. Cooling system: PVC negative pressure flexible duct is used in the cooling system of mechanical equipment, which helps to discharge the hot air generated during the operation of the machine and keep the equipment at the appropriate working temperature to improve efficiency and prolong the service life.

2. Exhaust gas emission: It is suitable for the exhaust gas treatment system of mechanical equipments to discharge the harmful gases and fumes effectively and prevent the harm to the environment and operators.

3. Dust control: In processing machinery (such as milling machines, lathes and grinders), the use of flexible air ducts to collect the dust generated, to maintain a clean working environment and improve the safety and health of employees.

4. Hydraulic System Ventilation: In hydraulic machinery, negative pressure air ducts can be used for ventilation and gas exhaust, reducing air bubbles and gas buildup and enhancing the operational stability of the system.

5. Airflow control for precision equipment: In precision machinery and equipment where airflow and pressure need to be controlled, the use of PVC negative-pressure flexible ducts ensures a smooth flow of air, which improves the performance and efficiency of the equipment.

6. Computer Room Ventilation: In computer rooms equipped with multiple pieces of mechanical equipment, flexible ducts can be used for ventilation to help maintain the ventilation needs of the equipment and prevent overheating.

7. Wastewater Treatment Equipment: In mechanical equipment in wastewater treatment plants, it is used to vent gases generated during the wastewater treatment process to ensure environmental safety and normal operation of the equipment.

8. Mold Cooling: In the process of mold manufacturing and use, flexible air ducts can be used to cool the molds, helping to keep the temperature of the molds stable and preventing deformation and damage.

Frequently Asked Questions