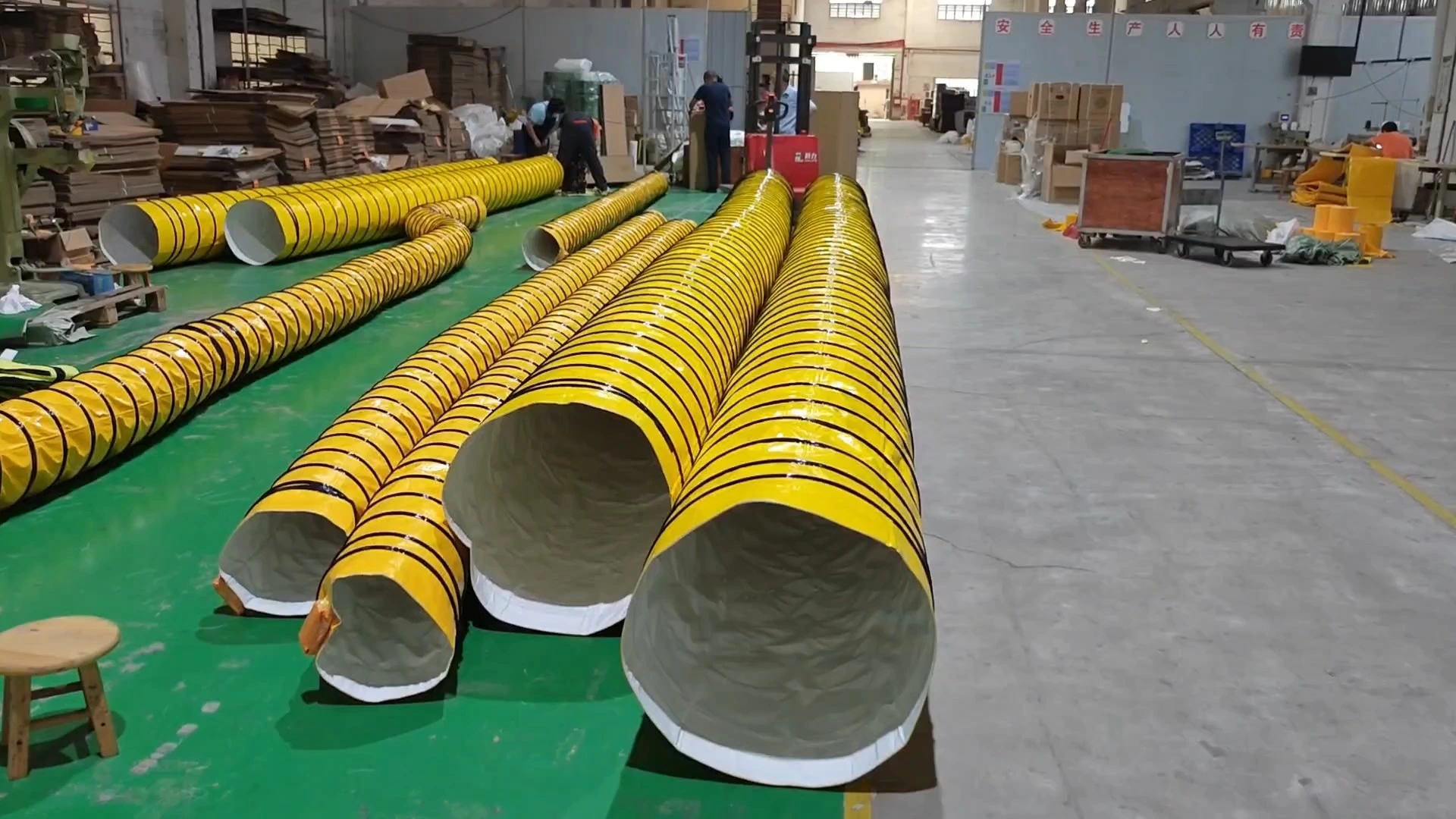

insulation PVC flexible duct for Air conditioning chiller NUOENWEI

Material & Construction:

MATERIAL: High-quality PVC ensures durability and solidity while the surface is smooth to prevent dust accumulation.

INSULATION: External insulation is designed to reduce heat transfer and prevent condensation, ensuring high chiller performance.

Features:

Flexibility: The piping design allows for free bending according to installation needs, allowing easy access to a variety of spaces.

Lightweight: The lightweight design significantly reduces transportation and installation difficulties.

Corrosion resistance: PVC material can withstand a wide range of chemicals and is suitable for a wide range of environments.

Low Temperature Resistance: Maintains performance in extreme temperatures to ensure safe use.

Application Areas:

Mainly used in air conditioning chiller ventilation systems, connecting the indoor unit to the external chiller.

Can be used in air conditioning, ventilation and heating systems of buildings to ensure air circulation.

Performance Advantages:

Energy efficiency improvement: optimize system performance and reduce operating costs by reducing energy loss.

Noise reduction: Good sound insulation improves the comfort of the indoor environment.

Easy installation and maintenance: The design simplifies the installation process and reduces labor costs.

Insulation PVC Flexible Duct for Air Conditioning Chiller

Insulation PVC Flexible Duct is a high-performance ventilation duct designed for heating, ventilation and air conditioning systems, and is especially suited for air conditioning chiller applications. It combines high-quality PVC material with insulation designed to reduce heat loss, improve energy efficiency and extend equipment life. The ducting not only ensures smooth air flow, but also prevents condensation and mold, providing buildings with a comfortable indoor environment.

Related Parameters

|

thickness |

3mm |

|

diameter |

100mm-1500mm |

|

Temperature Range |

- 15℃ to + 80 ℃ |

|

Certification |

ISO9001 |

|

Color |

Blue, yellow or customized colors |

|

Feature |

high quality can be used for both air supply and suction |

|

Application |

It is used with grain cooler or other special air conditioner, grain warehouse, outdoor tent and other efficient transportation of cold and hot air |

Product Advantages

1. Energy Efficiency:

- The insulation layer significantly reduces thermal transfer, minimizing energy loss and enhancing the overall efficiency of HVAC systems.

2. Flexibility:

- Designed for easy installation, the flexible duct can be bent and shaped to fit various architectural layouts, simplifying the routing process.

3. Lightweight:

- The lightweight design facilitates easy handling and reduces installation labor costs, making it a convenient choice for contractors.

4. Durability:

- Made from high-quality PVC, the duct is resistant to corrosion, moisture, and chemicals, ensuring long-lasting performance in diverse environments.

5. Reduced Noise Levels:

- The insulation effectively dampens sound transmission, contributing to a quieter indoor atmosphere, which is essential for residential and commercial spaces.

6. Low Maintenance:

- The smooth inner surface reduces dust accumulation, requiring less frequent cleaning and maintenance compared to other duct materials.

7. Cost-Effective:

- Its combination of performance and durability makes it an economical choice for HVAC systems, ultimately lowering lifetime operational costs.

8. Versatile Applications:

- Suitable for various environments, including residential, commercial, and industrial settings, particularly in connection with air conditioning and ventilation systems.

9. Easy Installation:

- The design allows for quick and straightforward installation, even in hard-to-reach areas, reducing project timelines.

10. Temperature Control:

- Designed to maintain consistent temperatures, helping to optimize comfort levels in any space.

Application Scenario

1. Residential HVAC Systems:

- Used in homes to connect heating and cooling units to air handling systems, ensuring efficient temperature control and comfort in living spaces.

2. Commercial Buildings:

- Installed in office buildings, shopping malls, and restaurants to distribute conditioned air and maintain a pleasant environment for occupants and customers.

3. Industrial Facilities:

- Employed in factories and warehouses for effective ventilation, controlling humidity levels and providing fresh air to workspaces.

4. Data Centers:

- Utilized for cooling systems to efficiently manage heat produced by servers and equipment, maintaining optimal operating temperatures.

5. Pharmaceutical and Food Production:

- Applied in environments requiring strict temperature and humidity control to protect sensitive products and maintain compliance with industry standards.

6. Cooling Towers:

- Used in conjunction with chillers to transport chilled water or air, helping to enhance cooling efficiency in large systems.

7. Greenhouses:

- Installed to facilitate proper air circulation and temperature management, crucial for promoting healthy plant growth.

8. Centralized Air Conditioning Systems:

- Integrated into large central systems to distribute cooled air effectively throughout the building, ensuring balanced airflow in multiple zones.

Frequently Asked Questions