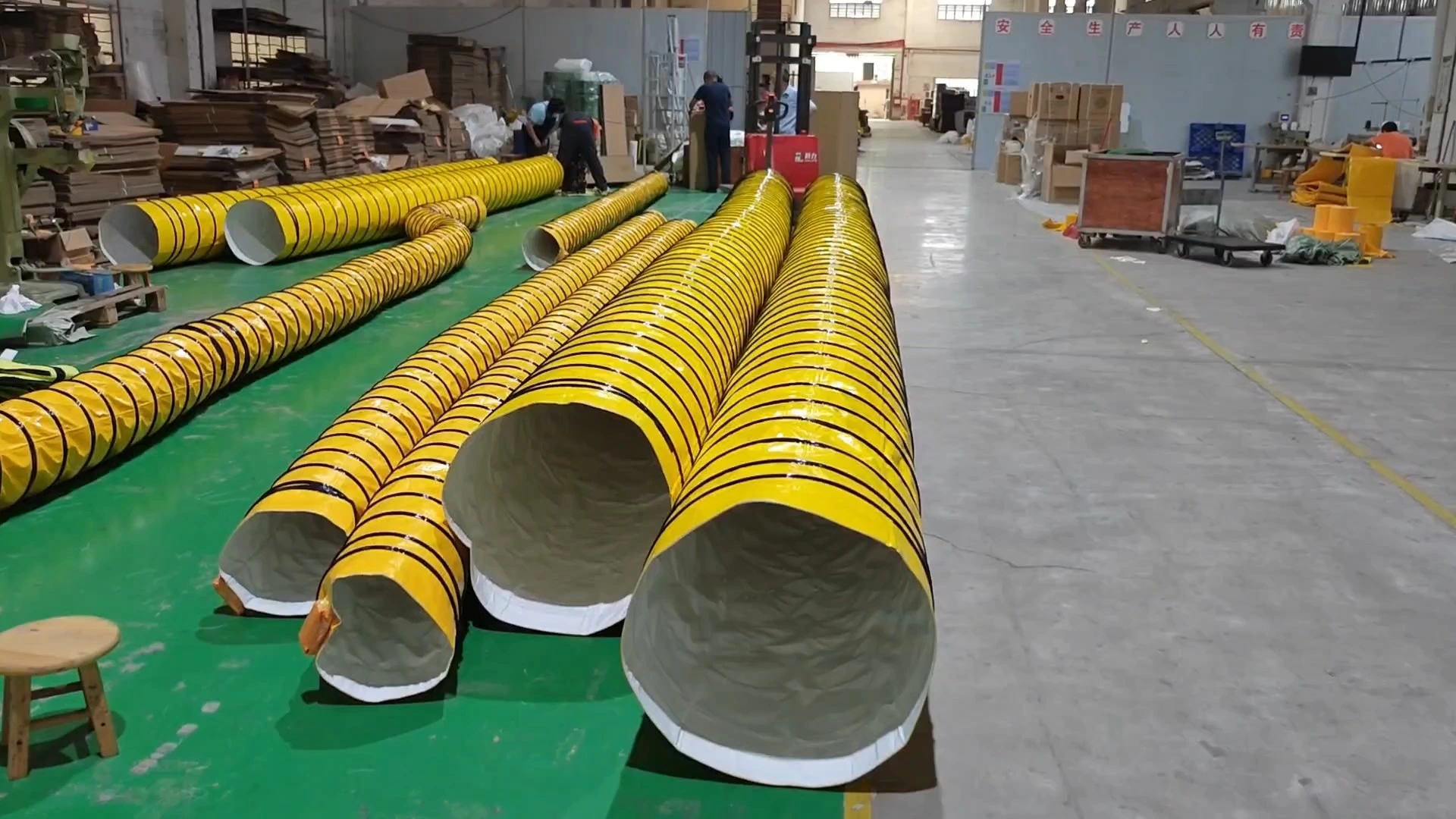

air conditioning flexible duct made of PVC and insulation material for grain cooler NUOENWEI

This air conditioning insulation and ventilation hose is manufactured with high-performance PVC and heat-resistant insulation to ensure reliable use in a variety of climates. The inner insulation effectively reduces heat loss and saves energy, while the outer PVC layer resists corrosion and abrasion. Suitable for cold and hot air transportation in specialty air conditioning systems, it is suitable for a wide range of application scenarios, including commercial and industrial. Designed to be lightweight and flexible, the product is easy to install and maintain, and can meet the needs of different users.

air conditioning flexible duct

Our PVC and Insulation Air Conditioning Insulated Ventilation Hose combines excellent insulation with corrosion resistance and is designed for specialty air conditioning and ventilation systems. Its flexibility allows for easy installation in industrial and commercial environments, effectively reducing energy consumption and increasing efficiency of use.

Related Parameters

|

thickness |

3mm |

|

diameter |

100mm-1500mm |

|

Temperature Range |

- 15℃ to + 80 ℃ |

|

Certification |

ISO9001 |

|

Color |

Blue, yellow or customized colors |

|

Feature |

high quality can be used for both air supply and suction |

|

Application |

It is used with grain cooler or other special air conditioner, grain warehouse, outdoor tent and other efficient transportation of cold and hot air |

Product Advantages

1. Superior Insulation: The combination of PVC and insulation material minimizes heat transfer, ensuring optimal temperature retention during air transport, which leads to energy savings.

2. Flexible Design: The lightweight and flexible properties allow for easy installation in tight spaces and various configurations, accommodating different ventilation and air conditioning setups.

3. Corrosion Resistance: Made from high-quality PVC, the ducting is resistant to moisture and corrosive elements, which enhances its durability and reliability over time.

4. High Durability: Engineered to withstand wear and tear, this duct can handle high pressure and varying temperatures, making it suitable for both residential and commercial applications.

5. Energy Efficiency: By effectively maintaining the desired temperature of the air, this duct helps reduce energy consumption, lowering utility costs and enhancing overall system efficiency.

6. Noise Reduction: The insulation layer also helps to dampen noise generated by the HVAC system, resulting in a quieter environment for users.

7. Easy Maintenance: Smooth inner surfaces facilitate airflow and make it easy to clean, ensuring consistent performance and hygiene, especially in food storage applications.

8. Versatile Applications: Ideal for a range of environments, including residential air conditioning, commercial ventilation systems, industrial applications, and agricultural settings.

9. Environmentally Friendly: Made from materials that meet environmental standards, ensuring safety and compliance for various applications.

10. Cost-Effective Solution: The combination of durability, energy efficiency, and low maintenance costs makes this ducting a cost-effective choice for effective air management.

Application Scenario

Used in conjunction with grain coolers and other specialized air conditioners, grain warehouses, outdoor tents and other equipment, the insulated air ducts can efficiently transport hot and cold air and improve the system's thermal energy utilization efficiency. Specific application scenarios include:

Temporary offices and activity places: Insulated air ducts can be connected to portable mobile air conditioners for use in temporary offices, conference rooms, exhibition halls and other activity places to quickly deliver hot and cold air into the room to maintain a comfortable temperature and good ventilation.

Environmental Waste Heat Recirculation System: In factories and commercial buildings, the insulated air ducts are suitable for environmental waste heat recirculation low loop temperature high temperature heat pump. The system can effectively transfer the low ambient temperature hot water or hot air produced by the heat pump to each area that needs to be heated, and at the same time reduce the heat loss and improve the energy utilization.

Warehouse Coolers: For temperature-sensitive warehouses such as food and pharmaceuticals, insulated air ducts can quickly transport the cool air generated by warehouse coolers to each corner, maintaining a uniformly cool environment and ensuring the quality of stored goods.

Grain dryers: In the grain drying process, dryers often require hot air or steam. Insulated air ducts efficiently transport hot air from the dryer to the drying area, ensuring drying efficiency and minimizing energy loss.

Grain coolers: Grain coolers can be used for temperature control in grain storage. Insulated air ducts efficiently transport the cool air produced by the chiller to the storage bins or warehouses, keeping temperatures low to prevent grain spoilage.

When used in conjunction with such equipment, insulated air ducts can significantly improve the overall system's efficiency in terms of heat utilization. Proper design and installation methods ensure efficient transfer of hot and cold air flows, reducing energy losses and thus significantly optimizing production and storage processes.

Frequently Asked Questions